Fieldbus Communication Protocols: The Backbone of Industrial Automation – Discover how fieldbus protocols enable seamless communication and data exchange between devices in industrial automation systems. Learn about popular protocols like Foundation Fieldbus, Profibus, CAN, and their key features and benefits.

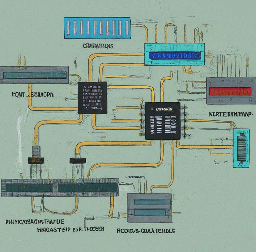

Fieldbus protocols serve as the digital nervous system of industrial automation systems, enabling seamless communication between intelligent devices. These protocols provide a standardized way for devices such as sensors, actuators, and controllers to exchange data and coordinate their actions.

Key Features of Fieldbus Protocols

- Standardization: Fieldbus protocols adhere to industry-wide standards, ensuring interoperability and compatibility between devices from different manufacturers.

- Real-time communication: They are designed to provide timely data exchange, critical for applications that require rapid responses, such as process control and machine automation.

- Device management: Fieldbus protocols offer features for device configuration, diagnostics, and maintenance, simplifying the management of industrial networks.

- Data integration: They facilitate the integration of field devices with higher-level control systems and enterprise resource planning (ERP) software.

Popular Fieldbus Protocols

- Foundation Fieldbus (FF): A high-level fieldbus protocol that supports a wide range of communication services, including device diagnostics, configuration, and parameterization. FF is commonly used in process automation industries.

- Profibus: A versatile fieldbus protocol that offers a range of profiles for different applications, including process automation, discrete manufacturing, and building automation. Profibus is widely adopted in various industrial sectors.

- CAN (Controller Area Network): A popular choice for automotive applications, CAN has also found its place in industrial automation, especially for low-speed, real-time communication.

- DeviceNet: A fieldbus protocol specifically designed for discrete manufacturing and automation applications. DeviceNet offers features like real-time communication and device management.

- Interbus: A fieldbus protocol used primarily in European industrial automation. Interbus is known for its high speed and reliability.

Benefits of Using Fieldbus Protocols

- Increased efficiency: Fieldbus protocols streamline data exchange and coordination between devices, leading to improved process efficiency and productivity.

- Reduced wiring: By eliminating the need for point-to-point wiring, fieldbus protocols can significantly reduce the cost and complexity of installation.

- Enhanced diagnostics: Built-in diagnostic features enable early detection and resolution of faults, minimizing downtime.

- Scalability: Fieldbus protocols can accommodate a wide range of devices and network sizes, making them suitable for both small-scale and large-scale industrial applications.

Challenges and Future Trends

- Compatibility: Ensuring compatibility between devices from different manufacturers can sometimes be a challenge, particularly when dealing with legacy systems.

- Security: As industrial networks become increasingly interconnected, cybersecurity threats pose a significant risk. Fieldbus protocols need to incorporate robust security measures to protect against cyberattacks.

- Integration with emerging technologies: The integration of fieldbus protocols with emerging technologies like IoT, cloud computing, and artificial intelligence will be crucial for realizing the full potential of digitalization in industrial automation.

In conclusion, fieldbus protocols are essential components of modern industrial automation systems. By providing a standardized and efficient means of communication between devices, they contribute to improved productivity, reliability, and flexibility. As technology continues to advance, fieldbus protocols will undoubtedly play a key role in shaping the future of industrial automation.

Home | Join us on Facebook, Twitter, YouTube, Instagram, Quora, Reddit, LinkedIn, Pintereset, Blogger.