Delta ASDA-A2 Servo Drive – Find comprehensive resources for Delta ASDA-A2 servo drives, including product catalogs, manuals, price list, programming guides, fault, alarm, warnings & software support. Get expert assistance for troubleshooting and optimization.

Delta ASDA-A2 Servo Drive is a high-performance system designed for demanding motion control applications. It utilizes high-resolution encoders, often 20-bit, for very accurate positioning.

Features

Delta ASDA-A2 Servo Drive – To meet the demanding requirements of motion control applications in industrial automation and satisfy the needs of high-precision positioning control requested by machine designers and system integrators.

- High Precision: It utilizes high-resolution encoders, often 20-bit, for very accurate positioning.

- Advanced Motion Control: Built-in electronic cam (E-CAM) functionality is ideal for synchronized motion applications like flying shear and rotary cutoff.

- Versatility: Supports various communication protocols, including CANopen, DMCNET, and EtherCAT, for seamless integration.

- User-Friendly Features: ASDA-A2-Soft configuration software simplifies parameter settings and motion programming.

- Full Closed-Loop Control: Reduces the impact of mechanical imperfections.

Specifications :

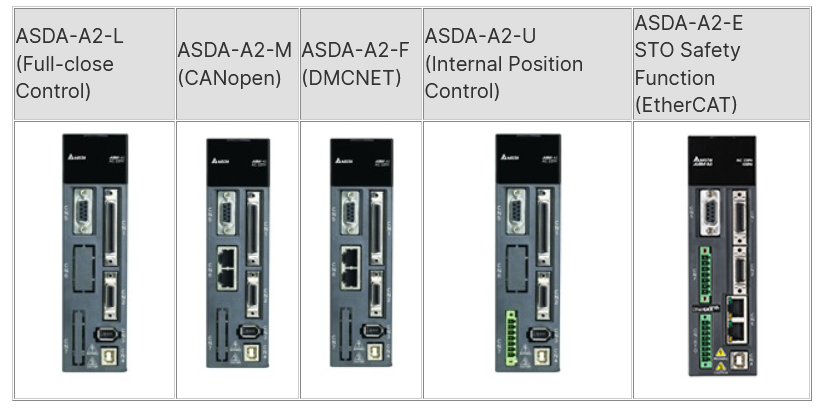

- There are five models of ASDA-A2 series: ASDA-A2-L, ASDA-A2-M, ASDA-A2-F, ASDA-A2-U, ASDA-A2-E.

High Precision Control

ECMA series servo motors feature incremental encoder with 20-bit resolution (1280000 pulses/revolution). Existing functions to meet the requirements from delicate process have been enhanced. Stable rotation at low speed has also been achieved.

Superlative Vibration Suppression

Built-in automatic low-frequency vibration suppression (for crane control): two vibration suppression filters are provided to minimize the vibration at machine edges automatically and sufficiently.

Built-in automatic high-frequency resonance suppression: two auto notch filters are provided to suppress the mechanical resonance automatically.

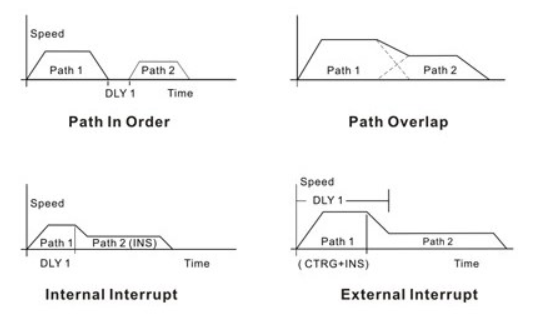

Flexible Internal Position Mode (Pr Mode)

- ASDA-A2-Soft configuration software provides internal parameter editing function for defining the path of each axis freely.

- 64 internal position settings are offered for continuous motion control.

- Destination position, speed and acceleration & deceleration commands could be changed in the middle of operation.

- 35 kinds of homing modes are available.

Unique Built-in Electronic Cam (E-CAM)

- Up to 720 E-CAM points.

- Smooth interpolation between points can be completed automatically to yield a flexible programming.

- ASDA-A2-Soft configuration software provides electronic cam (E-CAM) profile editing function.

- Applicable for rotary cutoff and flying shear applications.

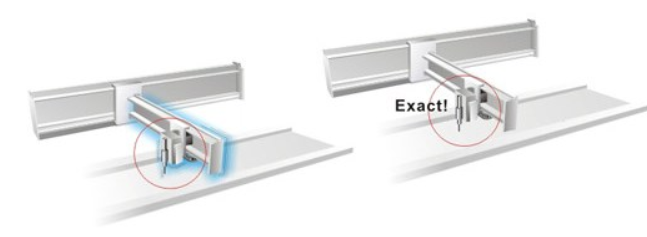

Full Closed-loop Control (Capable of reading second feedback signals)

- Built-in position feedback interface (CN5) is able to read second feedback signals from motor encoder and send the current position back to the drive to form a full closed-loop so that high accuracy position control can be accomplished.

- Reduce the effects of mechanical imperfections such as backlash and flexibility to ensure the position precision at machine edges.

Features of ASDA-A2-M:

- CANbus communication speed is 1M bps, in comply with CANopen DS301 standard.

- 3 CANmotion modes (Profile Position Mode, Interpolation Position Mode, Homing Mode) are provided for CANopen DS402 standard. Max. length of the communication cable can reach up to 40m (when using standard communication cable).

- Station configuration can be set via parameter settings.

- In conjunction with Delta’s PLC, it is able to save the wiring and establish Delta fieldbus system configuration.

Features of ASDA-A2-U:

- Max. 14 digital inputs.

- Using powerful “Pr mode” is able to perform complex motions.

- Quick connector is available for easy installation and use.

- Built-in DC 24V power supply is provided to simplify the wiring and save space.

Features of ASDA-A2-E :

- Touch probe function can be enabled with two dedicated Digital Inputs (DI) on CN7 or the external encoder.

- Integrated Safe Torque Off (STO) safety function according to the standards of EN 61800-5-2; IEC 61508, SIL2; IEC 62061, SIL2; ISO 13849-1, Cat.3 ,PL=d

- Wide power range coverage in both 220V and 400V

- Supports full-closed loop control

- Supports absolute type and incremental type ECMA Series servo motors

Applications :

The ASDA-A2 series is well-suited for applications requiring high precision and dynamic performance, such as:

- Precise carving machine,

- Precise lathe/milling machine,

- Double column type machining center,

- TFT LCD cutting machine,

- Robot arm,

- IC packaging machine,

- High-speed packaging machine,

- CNC processing equipment,

- Injection processing equipment,

- Label inserting machine,

- Food packaging machine,

- Printing etc.

Other Useful Link For ASDA-A2 Servo drive