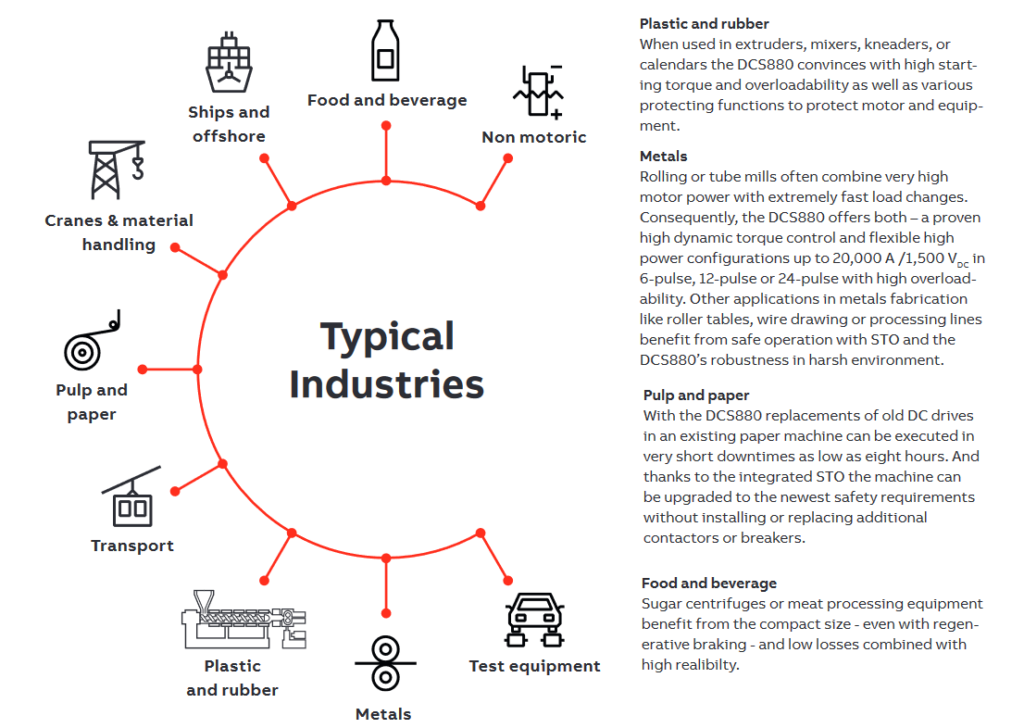

ABB DCS880 Drive Application & Features – DCS880 industrial drives are customized to meet the precise needs of industries such as oil and gas, mining, metals, cement, non motoric, material handling, pulp and paper, rubber and plastics, marine, water and wastewater, food and beverage and automotive. They control a wide range of applications such as cranes, extruders, winches, winders, conveyors, mixers, millstands, centrifuges, test benches, elevators, electrolysis, kiln.

Standard DCS880 features

DCS880 firmware includes the basic function of speed control, armature current, field current and motor voltage. The flexible design for command location enables field bus control or master- follower control or control from hardware signals as well as a mixed structure. The design of drive logic enables a drive reaction defined by Profibus standard but can also configured to adapt classic command structures. Integrated safe torque off (STO).

Safe torque off for implementing safe machinery

- SIL 3, PL e Extensive I/O connections

- The DCS880 features extensive I/O connections for flexible configuration in various applications

- Colored terminals for easy configuration

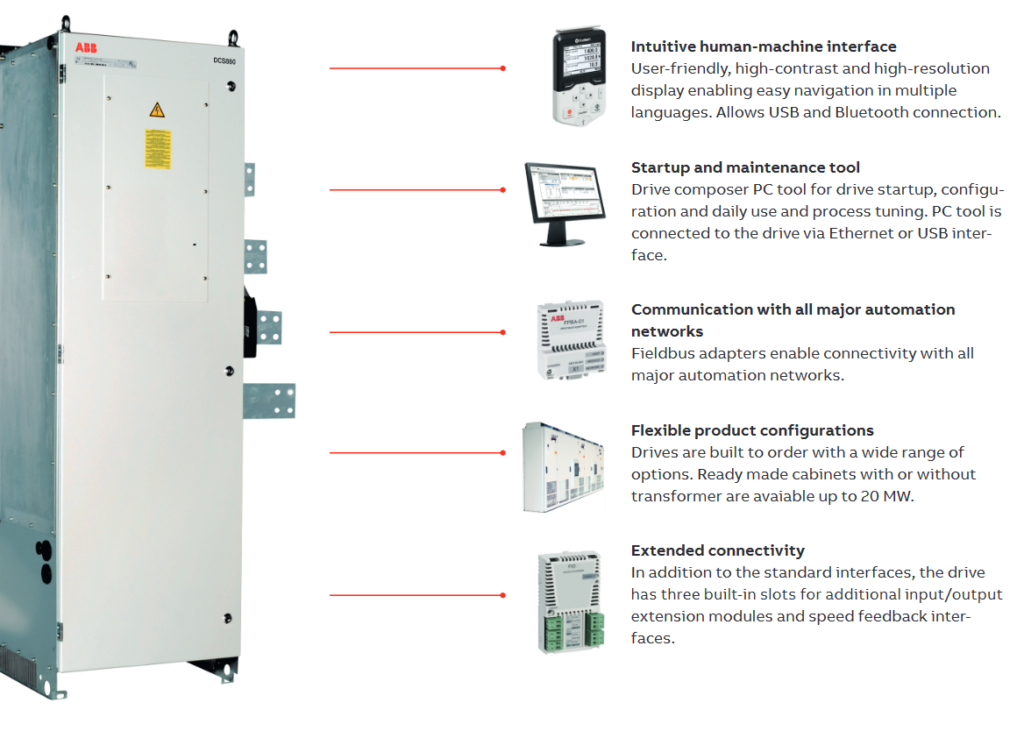

Assistant control panel and primary settings

- The ACS-AP-I assistant control panel speaks 16 different languages

- USB interface for PC and tool connection

- Help button for problem-solving Commissioning Assistants DCS880 includes a eight step assistant to set up the drive. The assistant is available via control panel and Drive Composer Pro PC-tool. Following comissioning steps are covered:

- Name plate data

- Standard I/O

- Field current controller with auto tuning

- Armature current controller with auto tuning

- First motor turning

- Speed feedback selection with autodetect of speed feedback device

- Speed controller with auto tuning

- Field weakening with auto tuning

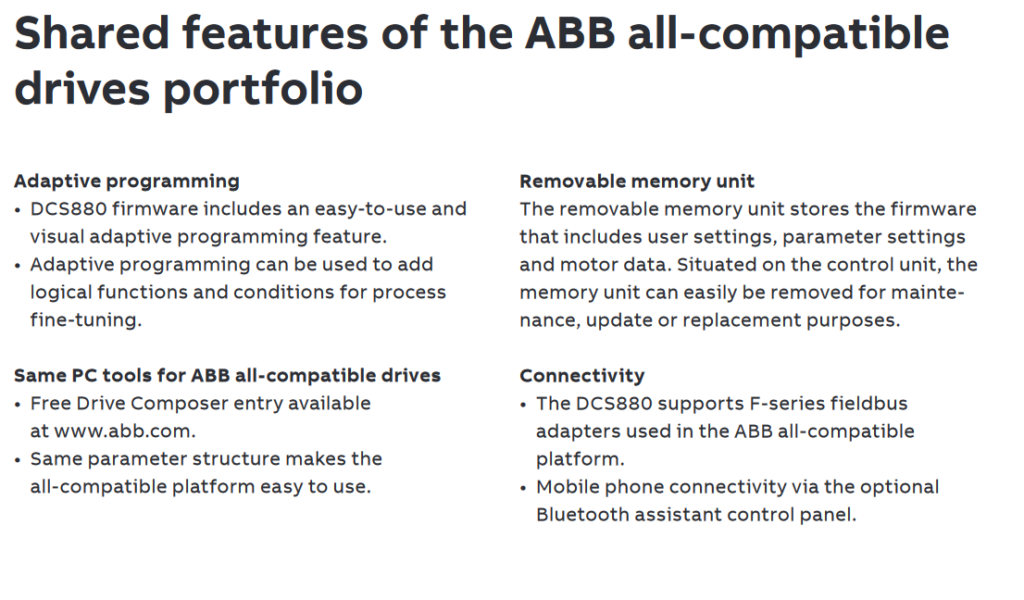

Adaptive programming

- DCS880 firmware includes an easy-to-use and visual adaptive programming feature.

- Adaptive programming can be used to add logical functions and conditions for process fine-tuning.

Same PC tools for ABB all-compatible drives

- Free Drive Composer entry available at www.abb.com.

- Same parameter structure makes the all-compatible platform easy to use.

Removable memory unit

The removable memory unit stores the firmware that includes user settings, parameter settings and motor data. Situated on the control unit, the memory unit can easily be removed for maintenance, update or replacement purposes.

Connectivity

- The DCS880 supports F-series fieldbus adapters used in the ABB all-compatible platform.

- Mobile phone connectivity via the optional

Bluetooth assistant control panel.

The power converter modules DCS880-S have the protection class IP00 and are to be mounted in a cubicle or finger protected area. There are different sizes (H1 – H8), graduated in terms of current and voltage ranges.

All units are equipped with the DCS880 Control Panel. It can be snapped into place on the power converter module or installed in the switch gear cubicle door by means of a mounting kit.

Accessories such as external fuses, line reactors etc. are also available, to complete the drive system.

All converter modules up to 525 V and 1000 A (H1 … H4) are equipped with field exciters.

The power section of the converters is available as single (2-Q) bridge or double (4-Q) bridge. 4-Q drives are required for regenerative breaking. 4-Q drives can be built by:

- Double (4-Q) armature bridge or

• Single (2-Q) armature bridge plus a double (4-Q) field converter bridge

Reference variables

The voltage characteristics are shown in the table beside. The DC voltage characteristics have been calculated using the following assumptions:

- U VN = rated input terminal voltage, 3-phase

- Voltage tolerance ±10 %

- Internal voltage drop approx. 1 %

- If a deviation or a voltage drop has to be taken into consideration in compliance with IEC and VDE standards, the output voltage or the out- put current must be reduced by the actual factor according to the table on the right. If armature voltages higher than recommended are requested, please check carefully, whether your system is still working under safe conditions. The maximum output voltage of a 4-Q drive can be increased up to the level of U dmax 2-Q. Thus the torque reversal from motoring mode to generating mode increases up to 300 ms. This lowers the dynamics of the drive and is only recommended for non-dynamic applications (e.g. E-Stop function).

Applications