Optimize your ABB ACS800 drive performance by configuring parameters like motor data, control mode, ramp times, and more. This guide provides a comprehensive overview for efficient setup.

Here is step by step programming of ABB ACS800 drive:

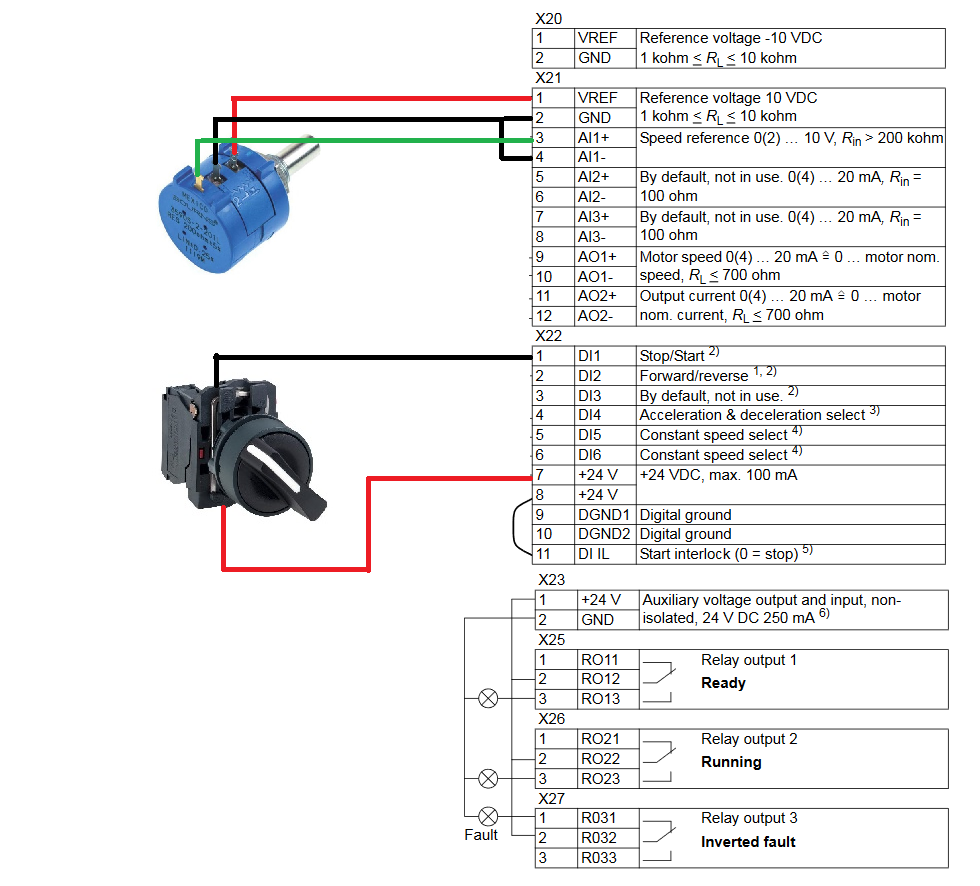

Step 1 – control wiring

Connect all control wiring for start/stop and speed reference. Below image show control wiring of ACS800 drive.

Step 2 – Power wiring

Connect input power wiring and motor wiring to the drive. Connect input supply to L1, L2 & L3 and connect motor wire at terminal U2, V2 & W2.

Step 3 – Parameters

Below list show all parameter used in ACS800 drive programming.

| Macro | |||

| 9902 | 1 | ABB Standard | |

| Motor data | |||

| 9905 | ……V | ||

| 9906 | …...A | ||

| 9907 | …...Hz | ||

| 9908 | …...rpm | ||

| 9909 | …...KW | ||

| Control Mode | |||

| 9904 | Vector | ||

| Scaler | |||

| 9910 | 1 | ID Mag | |

| 2 | Standard | ||

| 3 | Reduced | ||

| Linits | |||

| 2001 | …...rpm | Min Speed | |

| 2002 | …...rpm | Max speed | |

| 2003 | …...A | Max output current | |

| 2007 | …...Hz | Min freq | |

| 2008 | …...Hz | Max freq | |

| ACC/DEC Time | |||

| 2202 | …...s | Acc time 1 | |

| 2203 | …...s | Dec rime 1 | |

| 2004 | …...s | Acc time 2 | |

| 2005 | …...s | Dec time 2 |

Step 4 – Testing and Verification

- Start the Motor: Once programming is complete, you can initiate motor operation using the start/stop buttons on the control panel or through external control signals if configured.

- Monitor Performance: Observe the motor's operation and verify it functions as intended. If adjustments are needed, return to parameter setting mode and fine-tune the settings