Optimize your ABB DCS800 drive performance by configuring parameters like motor data, control mode, ramp times, and more. This guide provides a comprehensive overview for efficient setup.

Here is step by step programming of ABB DCS800 drive:

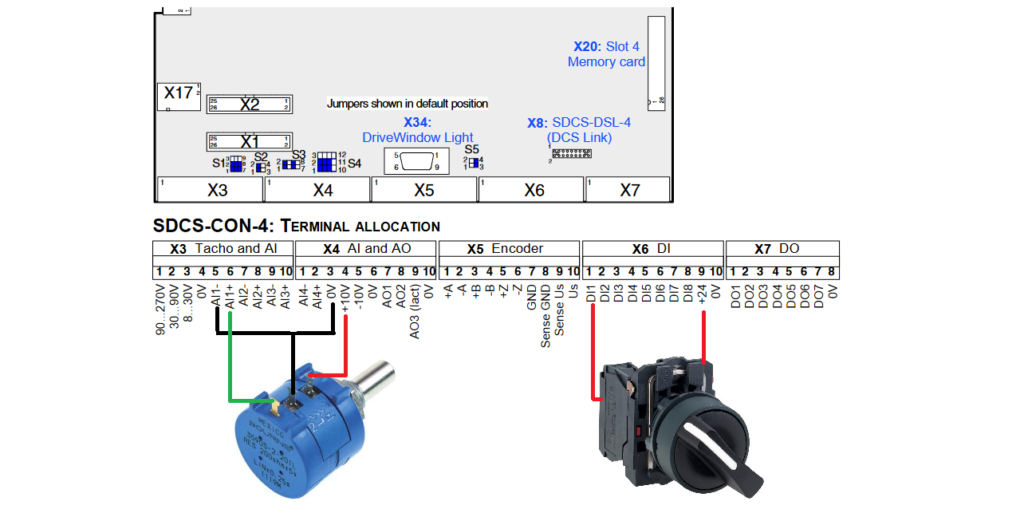

Step 1 – control wiring

Connect all control wiring for start/stop and speed reference. Below image show control wiring of DCS800 drive.

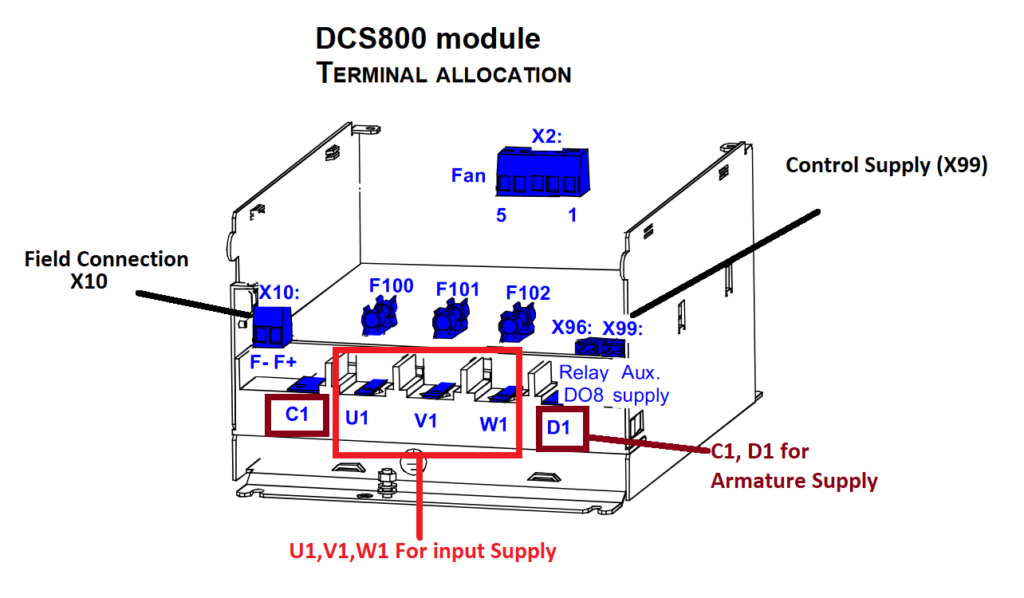

Step 2 – Power wiring

Connect input power wiring and motor wiring to the drive. Below image show power wiring of DCS800 drive.

Step 3 – Parameters

Below list show all parameter used in DCS800 drive programming.

| Motor Data | |||

| 99.02 | ……V | Armature Voltage | |

| 99.03 | ……A | Armature Current | |

| 99.04 | ……rpm | Base Speed | |

| 9910 | ……V | Nominal Mains Voltage | |

| 99.11 | ……A | Field Current | |

| Start/Stop | |||

| 10.15 | DI1 | Field Start/Stop | |

| 10.16 | DI1 | Armature Start/Stop | |

| 10.03 | Not Used | ||

| 10.06 | Not Used | ||

| 10.08 | Not Used | ||

| 10.09 | Not Used | ||

| 1020 | Not Used | ||

| 10.21 | Not Used | ||

| Speed Reference | |||

| 11.03 | 2 – AI1 | ||

| 13.03 | 1 = 0V-10V Uni | ||

| ACC/DEC Time | |||

| 22.01 | ……s | acceleration time 1 | |

| 22.02 | ……s | deceleration time 1 | |

| Limits | |||

| 20.01 | ……rpm | Minimum Speed | |

| 22.02 | ……rpm | Maximum Speed |

Step 4 – Testing and Verification

- Start the Motor: Once programming is complete, you can initiate motor operation using the start/stop buttons on the control panel or through external control signals if configured.

- Monitor Performance: Observe the motor's operation and verify it functions as intended. If adjustments are needed, return to parameter setting mode and fine-tune the settings.